Slow -Bio Casting Epoxy Resin – Slow Hardener Kit

$78.50 – $719.50 Online Discount

In-Store/Phone Orders (per unit/metre): $69.70 - 1.5ltr , $122.50 - 3ltr , $267.85 - 7.5ltr , $488.15- 15ltr , $877.05 - 30ltr

All epoxy resins are used at customers own risk, due to the large amount of variables when mixing and casting resin, ie. ambient temperature, volume of cast, additives. Reading the technical data sheet, testing and thorough research is highly recommended before attempting large pours.

- Description

- TDS/SDS

- Reviews (6)

Description

Perfect for river tables, deep pours and embedding pieces, our Bio Casting Epoxy Resin is a solvent free, water clear and low viscosity system. This bio-resin is a plant based formula which utilises renewable resources and reduces the levels of volatile organic compounds into the atmosphere. Bio Casting Epoxy Resin is optimised for clarity and air release to create crystal clear casting for hobby and art applications.

Applications: Ideal for casting, embedding and resin river table applications. This resin is suitable for larger applications and deep pours up to 50mm in thickness, where a longer working time is required, whilst the Fast Hardener is recommended for smaller, fast turnaround casting up to 20mm in thickness.

To find out how much Bio Casting Epoxy Resin – Slow Hardener you will need for your project Click Here

Mix Ratio

- 43 parts hardener to 100 parts resin by weight

- 50 part hardener to 100 part resin by volume

Note: Care should be taken when dispensing and mixing. Do not attempt to control the cure time by altering the hardener ratio. Please note that the room temperature will affect cure characteristics. Measure and mix Bio Casting Epoxy Resin with hardener using our range of Measuring and Mixing Equipment.

When purchasing 15L or 30L size – we recommend adding a Bung Tap to your order to make pouring easier.

Details

- Pot Life – 100g @ 25ºC (in air): 800-900 minutes

- Recommended temperature: 15-30°C *

- Cured to Solid State @ 25ºC: 72 hours

- Cured to maximum strength @ 25ºC: 7 days

- Shore ‘D’ Hardness @ 25ºC: 75

- Glass transition temperature (24hrs @ ambient + 16hrs @ 40ºC): 35ºC

- Easy clean up with Isopropyl Alcohol or Acetone

- Use Opaque, Translucent, Mica Powder or Pearlex pigments to colour resin

*At lower temperatures the resin will be thicker making it harder to mix and less able to release air bubbles during cure. The resin will also take longer to cure. In temperatures 15-20°C a heat will be necessary to remove air bubbles. Use below 15°C is not recommended.

When purchasing 15L or 30L size – we recommend adding a Bung Tap to your order to make pouring easier.

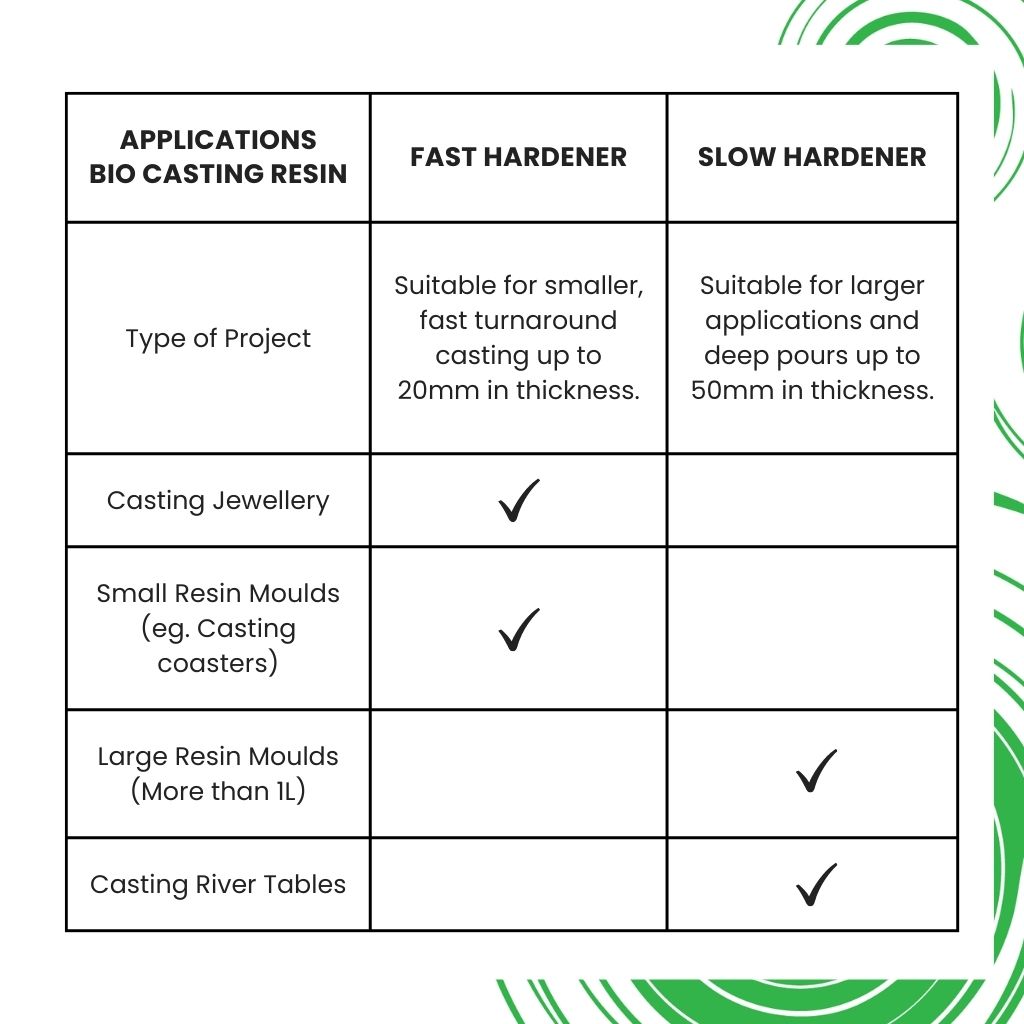

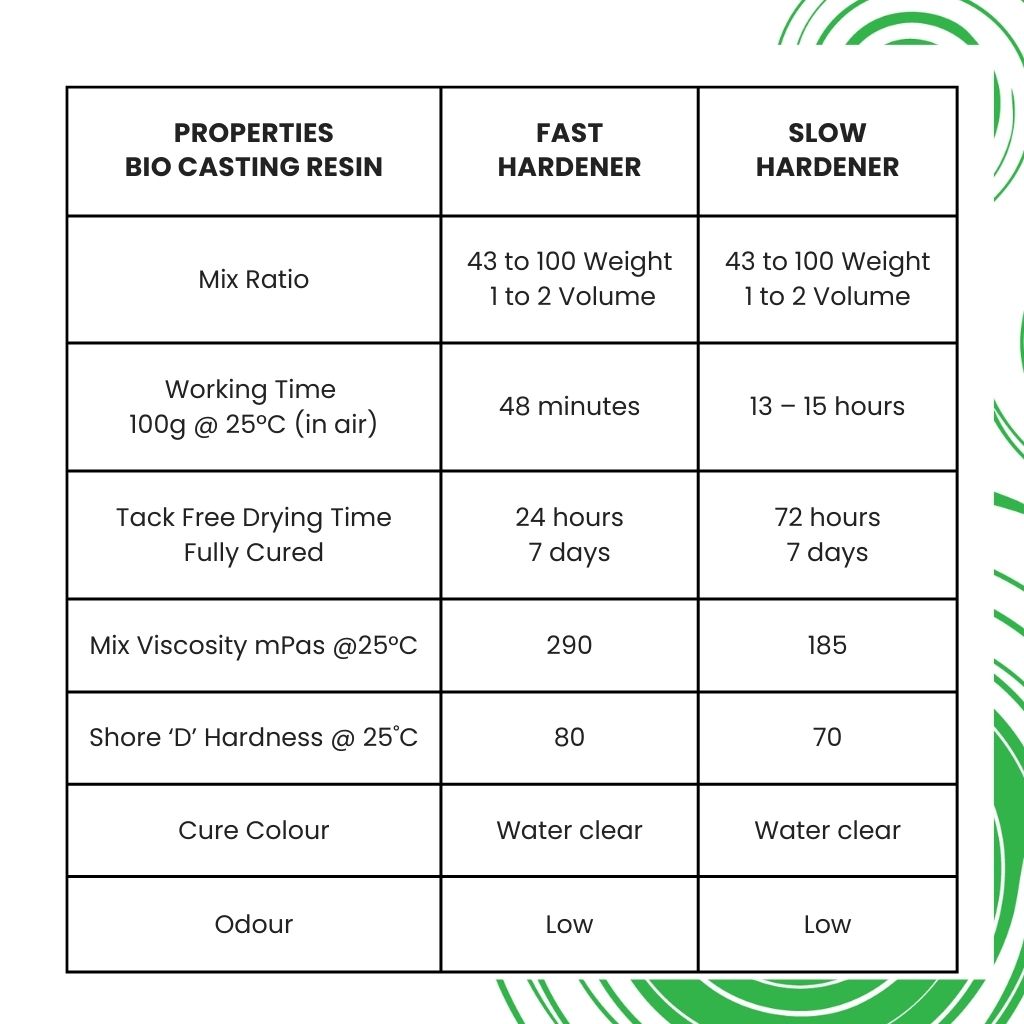

Not sure which Bio Casting Resin to use? This comparison chart will help you make the right choice!

| PROPERTIES | BIO CASTING RESIN | BIO CASTING RESIN |

|---|---|---|

| Mix Ratio |

43:100 Weight |

43:100 Weight |

| Working Time 100g @ 25ºC (in air) |

48 minutes |

13 – 15 hours |

| Tack Free Drying Time |

24 hours |

72 hours |

| Fully Cured |

7 days |

7 days |

| Mix Viscosity mPas @25°C

(From low viscosity eg water (1 cP), to high viscosity eg honey (10,000 cP) |

290 |

185 |

| Shore ‘D’ Hardness @ 25˚C

(It is determined as a number from 0 to 100 on the scales A or D. The higher the number, the higher the hardness) |

80 |

70 |

| Glass Transition Temperature

(24h@ ambient + 16h @ 40˚C) |

40°C |

35°C |

| Cure Colour |

Water Clear |

Water Clear |

| Odour |

Low |

Low |

| APPLICATIONS | ||

| Type of Project |

Suitable for smaller, fast turnaround casting up to 20mm in thickness. |

Suitable for larger applications and deep pours up to 50mm in thickness. |

| Casting Jewellery |

X |

|

| Small Resin Moulds

(eg. Casting coasters) |

X |

|

| Large Resin Moulds (More Than 1 Litre) |

X |

|

| Casting River Tables |

X |

|

Application

Use two clean plastic containers of equal volume to measure the correct proportion of resin and hardener. Pour the contents of both into a larger container and stir the two ingredients thoroughly, for at least 3 minutes –longer in cooler temperatures. Tip the mixed resin and hardener into a second large container and thoroughly mix again for a further 1-2 minutes. Ensure you stir the material slowly to keep air entrapment to a minimum.

Air bubble release is greatly enhanced by the use of a small heat gun or mini gas torch. Hold the torch approximately 100 to 150mm off the surface and keep moving the flame across the surface. Heat can be applied as many times as needed in the 800-900 minute working time. Inspect and remove any lint with tweezers. Bio Casting Epoxy Resin should be cured in a warm 25°C, dust free area.

Stay in the loop for the latest news, new products and specials! Keep and eye on our Facebook and Instagram pages.

Looking for some inspiration for your resin art creations? Head to our Pinterest and YouTube Channel for more ideas.

| Title | Type | Size | |

|---|---|---|---|

|

|

Bio Casting Epoxy Resin - SDS | application/pdf | 302 KB |

|

|

Bio Epoxy Slow Hardener - SDS | application/pdf | 304 KB |

|

|

Bio Casting Epoxy Resin - TDS | application/pdf | 179 KB |

John (verified owner) –

Very helpful staff

Paul (verified owner) –

Nina B. (verified owner) –

Excellent product, excellent packaging and fast packaging & delivery service.

Peter C. (verified owner) –

I have only done a test piece so far and it is still setting up but at this stage looks good. The photo is where the resin will go eventually. I estimate it will take 20+ ltrs

David (verified owner) –

Charles (verified owner) –